On a worksite, hard hats do more than meet a requirement—they serve as critical pieces of personal protective equipment (PPE), safeguarding workers from head injuries caused by falling objects, electrical hazards, and other dangers. Have you ever considered what the different hard hat colors represent?

But have you ever stopped to consider the meaning behind the different colors of hard hats?

Understanding these color codes isn’t just about following protocol; it’s about fostering a safer, more efficient workplace. At LBA University, we’re committed to equipping you with the knowledge you need to stay safe and compliant. Let’s explore the significance of hard hat colors, OSHA regulations, and why PPE training should be a priority for everyone.

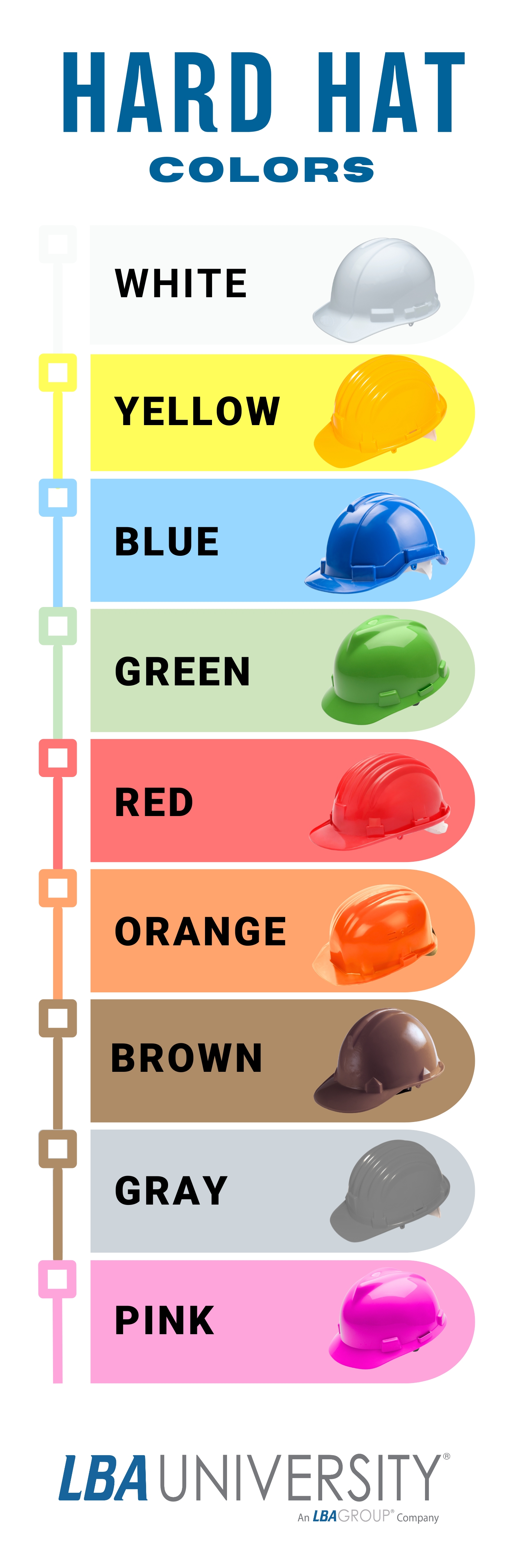

What Do Hard Hat Colors Mean?

Hard hat colors are often used to identify roles and responsibilities on a job site. While specific color codes can vary between industries and companies, here are some common standards:

- White: Worn by supervisors, managers, engineers, and architects. These individuals are often responsible for overseeing the site’s operations.

- Yellow: Typically designated for general laborers and earth-moving operators. This is one of the most common colors seen on worksites.

- Blue: Used by technical workers, such as electricians and carpenters. Blue can also signify medical personnel in some cases.

- Green: Reserved for safety officers or new workers who are undergoing training.

- Red: Often used for fire marshals or emergency personnel.

- Orange: Commonly assigned to road crews and heavy machinery operators, making them highly visible.

- Brown: Worn by welders or workers in high-heat environments.

- Gray: Sometimes used by site visitors or occasionally by specific trades, depending on company policy.

- Pink: Employers often reserve pink hard hats as spares. In some cases, they assign them to workers who forget their regular hard hats or use them to encourage compliance with PPE requirements in a lighthearted way.

Although these colors are widely recognized, it’s important to note that OSHA does not mandate specific hard hat colors. Employers, however, can establish their own color-coding systems to improve communication and ensure roles are easily identifiable.

OSHA Hard Hat Requirements

According to OSHA, hard hats must be worn in areas where head injuries are possible from falling objects or other hazards. Here are the key regulations:

- Standard Regulation: OSHA’s hard hat requirements are outlined in 29 CFR 1910.135.

- ANSI Compliance: OSHA-approved hard hats must meet the ANSI Z89 safety standard.

- Protection Levels: Hard hats must be designed to protect against impact, penetration, and electrical shock depending on the work environment.

- Type and Class Selection: Employers must ensure workers wear the appropriate type and class of hard hat:

- Type I: Provides top-of-head protection.

- Type II: Offers protection for both the top and sides of the head.

- Class G: General use, protects against low-voltage electrical hazards.

- Class E: Electrical, protects against high-voltage electrical hazards.

- Class C: Conductive, offers no electrical protection but is lightweight and ventilated.

By understanding and adhering to these regulations, workplaces can significantly reduce the risk of injuries.

Why PPE Matters

Personal protective equipment is your first line of defense against workplace hazards. According to OSHA, head injuries account for a significant number of workplace injuries. Properly worn PPE, including hard hats, can mean the difference between a minor scare and a life-altering injury.

Hard hats provide the following functions:

- Absorb and deflect impact from falling objects.

- Protect against electrical hazards (in specialized designs).

- Provide visibility and identification of roles on the job site.

Boost Your Workplace Safety with LBA University

At LBA University, we offer a comprehensive Personal Protective Equipment (PPE) course designed to help you understand and comply with safety standards. This course covers:

- The importance of PPE in ensuring safety.

- Employer and employee responsibilities regarding PPE use, maintenance, and inspection.

- Identifying and mitigating hazards to the head, eyes, face, respiratory system, hands, feet, and hearing.

- Selecting the correct PPE for specific tasks and understanding regulatory compliance.

Regulations Addressed:

- OSH Act Section 5(a)(1).

- 29 CFR 1910.132, 1910.133, 1910.134, 1910.135, and more.

- ANSI and ASTM standards for PPE safety.

Investing in safety training not only protects your workforce but also minimizes downtime and enhances productivity.

Enroll Today

Don’t wait until an accident happens. Equip yourself and your team with the knowledge to stay safe and compliant. Visit LBAUniversity.com to learn more about our Workplace Safety and Compliance courses and take the first step toward a safer workplace.

Remember, safety starts with you—and it’s as simple as putting on the right hard hat!